Fast Setup, accurate fills, proven reliability.

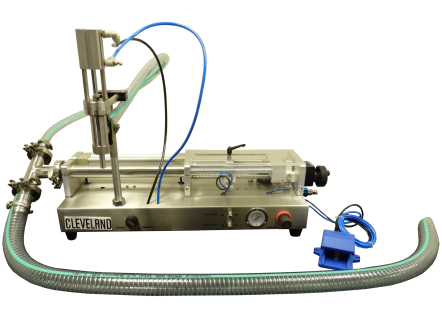

Cleveland Equipment's Semi-Automatic Piston Fillers: Precision Filling Without Electricity

Designed with foot pedals for various types of liquid and cream products, our wide range of pneumatic piston fillers will deliver precise, repeatable fills every time without the need for an electrical hookup. Whether you are a start-up or a high-volume producer, we have the ideal machine for your company - at many price points.

Popular Models

Choose a capacity that fits your fill volumes. We will configure nozzles and options for your product and container.

SGP-60 Cream and Liquid Piston Filler

Fill range 10-60ml:

- Pneumatically powered, no electricity needed

- Foot‑pedal or auto cycle

- Stainless steel hopper

and wetted parts

SGP-250 Cream and Liquid Piston Filler

Fill range 45-250ml:

- Versatile for thin or thick products

- Quick stroke adjustment for fast changeovers

- Positive shutoff nozzle options

SGY-1000 Liquid Only Piston Filler

Fill range 100-1000ml:

- Great for bottles and jugs

- Handles a wide variety of liquids

- Simple cleaning with tri‑clamp

fittings

Choosing the Right Piston Filler for Your Business

Reliable performance for diverse products and containers. Built for hygiene, safety and speed. Contact our team today to discuss your specific needs.

Accurate Volumetric Fills

No Electricity Required

Flexible Operation

Built to Last

Handles Many Containers

Lead times fill fast during peak months

Reserve your production slot now. We will finalize configuration, schedule and ship on your timeline. Priority is given to confirmed quotes.

Frequently asked questions

Do these piston fillers require electricity?

No. They are pneumatically powered with compressed air, which is ideal for wet areas or where electricity is not available.

Which products can they fill?

Thin liquids, oils, syrups, lotions, gels and thick creams. With the right nozzle and cylinder, you can also handle products with soft particulates.

How accurate are the fills?

These are volumetric fillers. When configured correctly, typical accuracy is around ±1% of target volume. Your product, temperature and operator cadence can influence results.

What air supply do I need?

Most semi-automatic units run on shop air 5cfm @ 90 PSI. Air consumption depends on model, piston size and cycle rate. We confirm requirements as part of your quote.

How fast can I run?

Cycle rates depend on fill volume, viscosity and operator pace. Many semi-automatic lines run about 15 to 20 cycles per minute under ideal conditions.

How do I clean and sanitize the machine?

Stainless steel wetted parts and tri-clamp connections allow quick disassembly and washdown. Follow your sanitation SOP. Some setups can support CIP.

Can I fill alcohol or flammable products?

Yes, pneumatic operation reduces ignition sources. Always follow local codes and choose compatible seals, hoses and nozzles for your formulation.

Will it work with different bottles and caps?

Yes. Piston fillers adapt to many containers. We match nozzle style and change parts to your bottle size and neck finish for clean cutoffs.

What information helps you quote accurately?

Product name, viscosity, desired fill range, target bottles per hour, container size and neck, available air supply, sanitation requirements and your timeline.

What are current lead times and warranty terms?

Lead times vary with demand and configuration. We include current lead time, warranty coverage and support details in your formal quote.

Request a Custom Quote

Tell us about your product, containers and target output. A specialist is standing by to assist with your questions.

Request a Custom Quote

Tell us about your product, containers and target output. A specialist will reply within one business day.